28BYJ-48步进电机驱动

介绍

参考《HAL快速入门与项目实战(基于DshanMCU-F407)_V1.0》

参考 步进电机

参考 步进电机原理

步进电机控制特点:

- 它是通过输入脉冲信号来进行控制的。

- 电机的总转动角度由输入脉冲数决定。

- 电机的转速由脉冲信号频率决定。

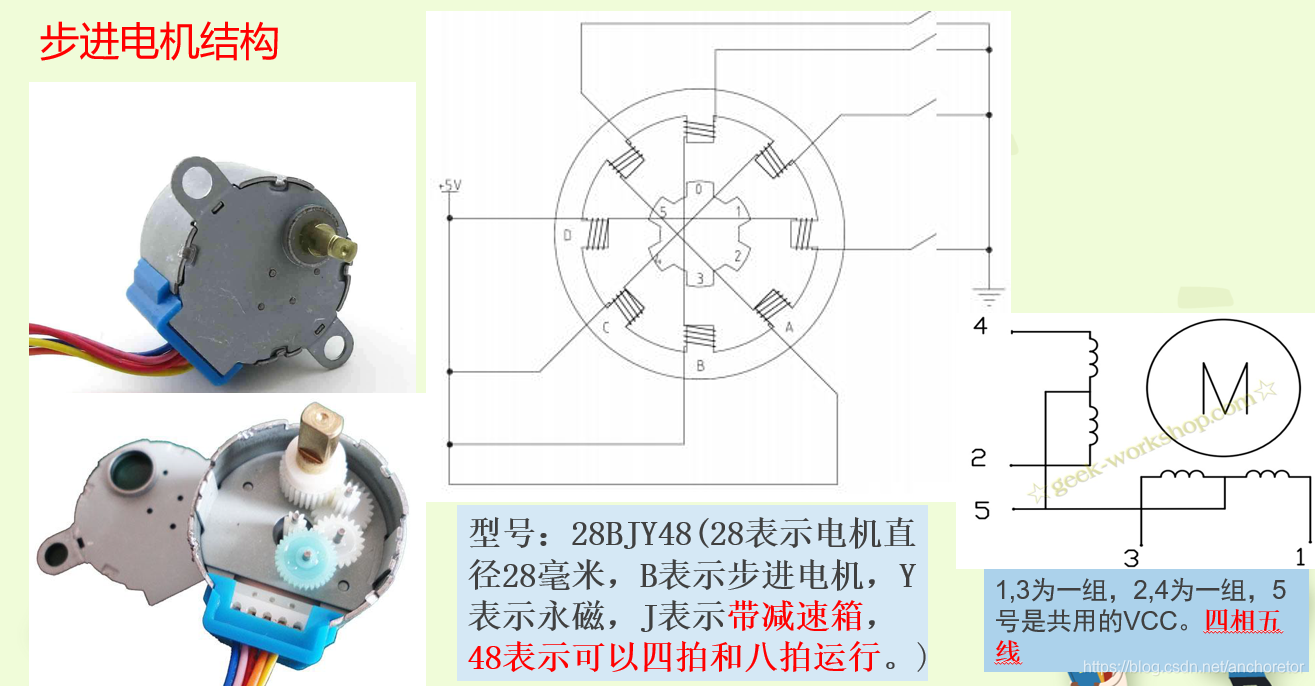

步进电机结构

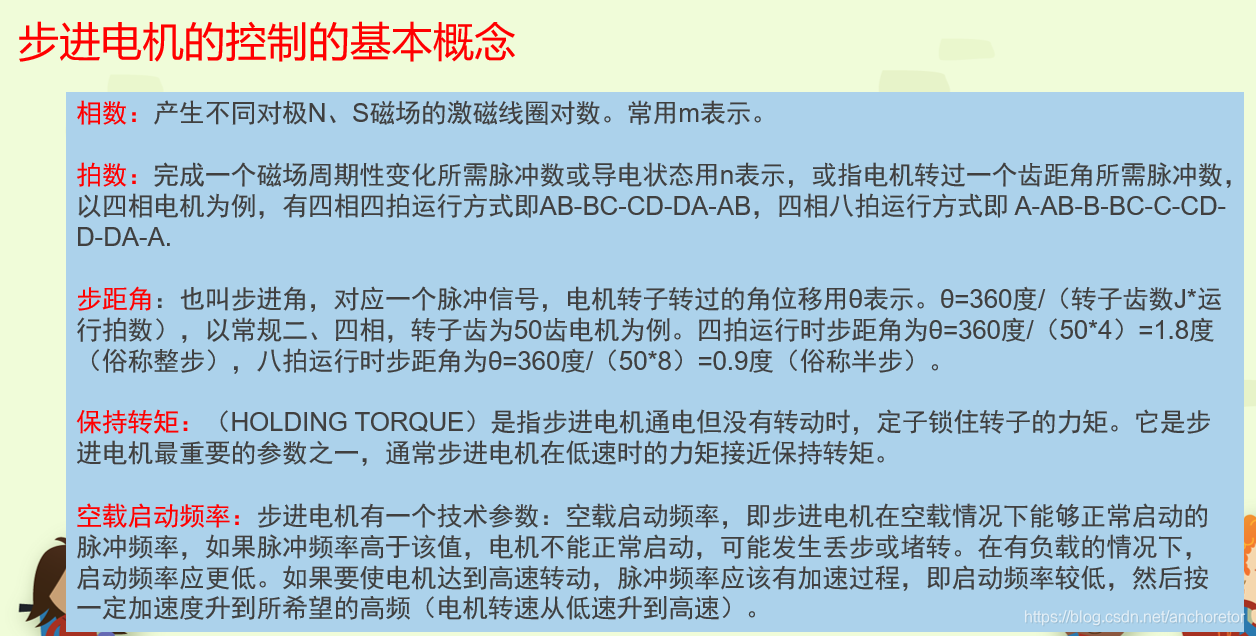

步进电机控制的基本概念

步进电机驱动拍数设置

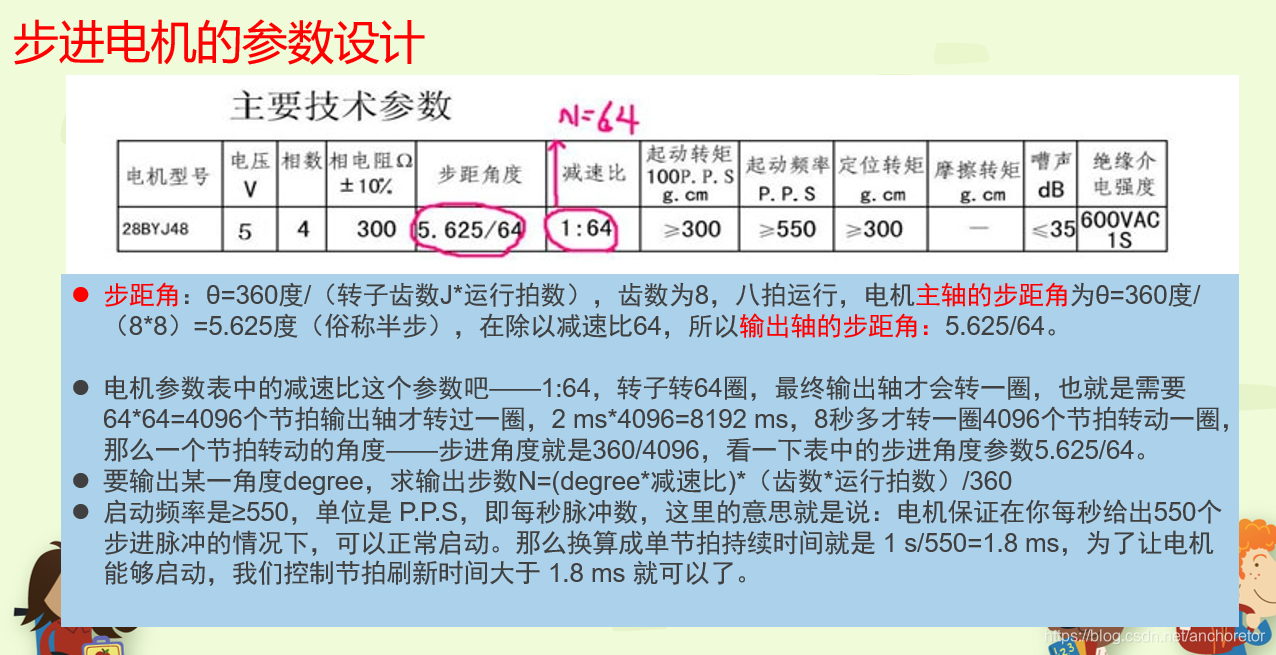

步进电机驱动参数设置

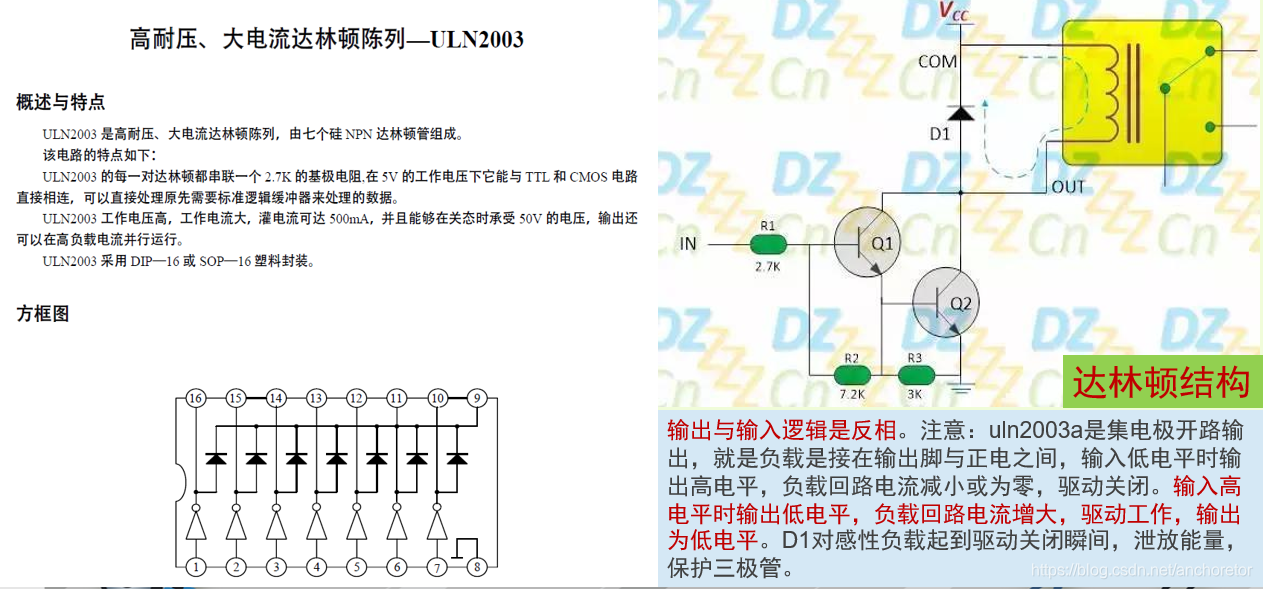

ULN2003驱动电路

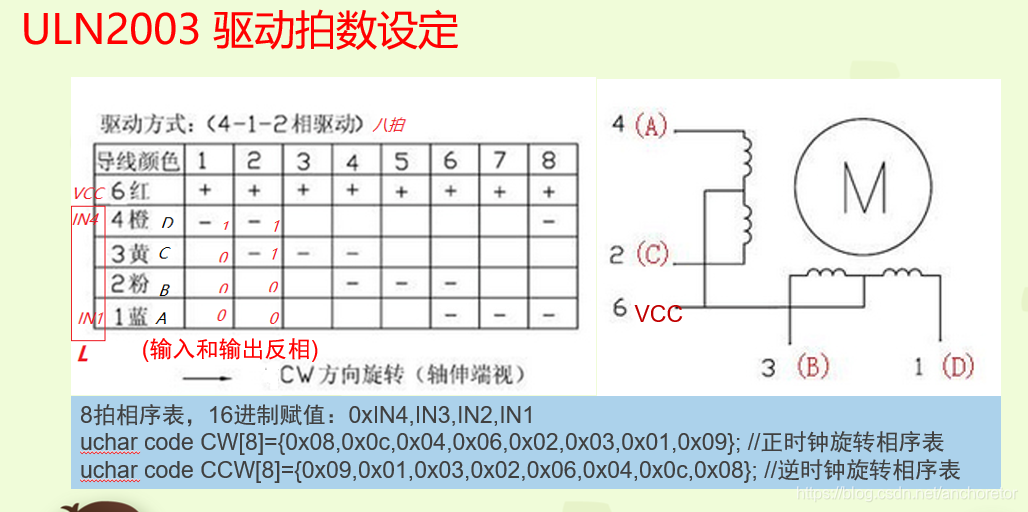

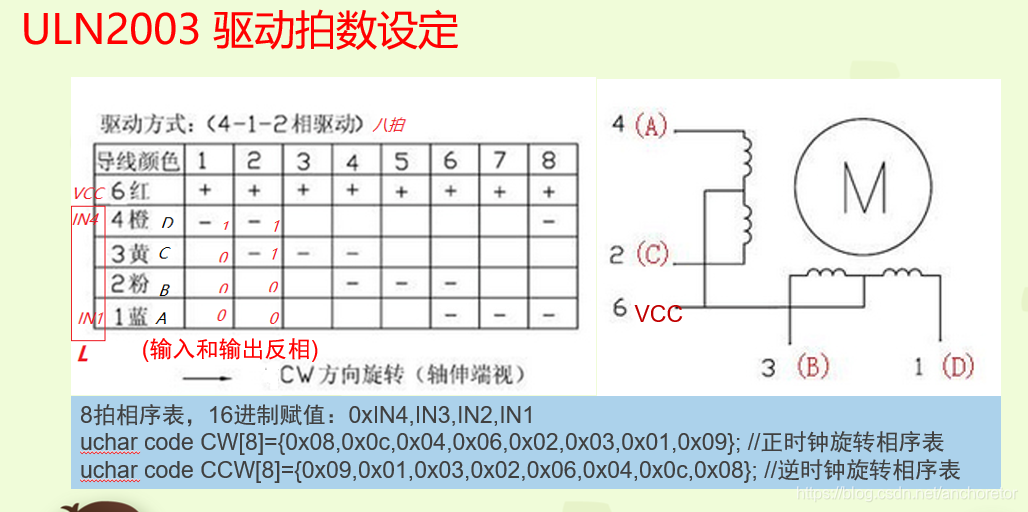

ULN2003驱动拍数设定

步进电机驱动程序

假设读者已有STM32定时器和PWM的相关概念

driver_28BYJ_48.h

#ifndef __DRIVER_28BYJ_48_H__

#define __DRIVER_28BYJ_48_H__

#ifdef __cplusplus

extern "C" {

#endif

typedef enum

{

STEP_MODE_HALF = 0x00,

STEP_MODE_FULL = 0x01

} motor_step_mode_t;

uint8_t a_28byj_48_init(TIM_HandleTypeDef *tim_handle);

uint8_t a_28byj_48_rotate(motor_step_mode_t step_mode, uint16_t time_delay_us, uint8_t direction);

uint8_t a_28byj_48_rotation_clockwise(motor_step_mode_t step_mode, uint16_t speed);

uint8_t a_28byj_48_rotation_counterclockwise(motor_step_mode_t step_mode, uint16_t time_delay_us);

void a_28byj_48_continuous_rotation(motor_step_mode_t step_mode, float speed_rpm, uint8_t direction);

uint8_t a_28byj_48_stop(void);

void a_28byj_48_toggle_direction(uint8_t *current_direction);

uint8_t a_28byj_48_position_control(motor_step_mode_t step_mode, int32_t target_position, int32_t *current_position, uint16_t time_delay_us);

void a_28byj_48_lock_position(void);

uint16_t a_28byj_48_set_speed(motor_step_mode_t step_mode, float speed_rpm);

uint8_t a_28byj_48_step_angle(motor_step_mode_t step_mode, float angle, uint8_t direction);

uint8_t a_28byj_48_microstep_drive(motor_step_mode_t step_mode, uint16_t microstep_count, uint16_t time_delay_us, uint8_t direction);

uint8_t a_28byj_48_accel_decel_drive(motor_step_mode_t step_mode, uint16_t total_steps, float max_speed_rpm, uint16_t acceleration, uint16_t deceleration, uint8_t direction);

#ifdef __cplusplus

}

#endif

#endif

driver_28BYJ_48.c

#include "driver_28BYJ_48.h"

#include "delay.h"

/* Timer handle and GPIO definitions */

static TIM_HandleTypeDef a_28byj_48_tim_handle;

#define MOTOR_28BYJ_48_IN1 TIM_CHANNEL_1

#define MOTOR_28BYJ_48_IN2 TIM_CHANNEL_2

#define MOTOR_28BYJ_48_IN3 TIM_CHANNEL_3

#define MOTOR_28BYJ_48_IN4 TIM_CHANNEL_4

#define MOTOR_28BYJ_48_GPIO_Port GPIOD

#define MOTOR_28BYJ_48_GPIO_Pin_IN1 GPIO_PIN_12

#define MOTOR_28BYJ_48_GPIO_Pin_IN2 GPIO_PIN_13

#define MOTOR_28BYJ_48_GPIO_Pin_IN3 GPIO_PIN_14

#define MOTOR_28BYJ_48_GPIO_Pin_IN4 GPIO_PIN_15

uint8_t current_step = 0;

/* Step sequences */

const uint8_t step_sequence_full[4] = {

0x01, /* 0b0001 IN1 */

0x02, /* 0b0010 IN2 */

0x04, /* 0b0100 IN3 */

0x08 /* 0b1000 IN4 */

};

const uint8_t step_sequence_half[8] = {

0x01, /* 0b0001 IN1 */

0x03, /* 0b0011 IN1 + IN2 */

0x02, /* 0b0010 IN2 */

0x06, /* 0b0110 IN2 + IN3 */

0x04, /* 0b0100 IN3 */

0x0C, /* 0b1100 IN3 + IN4 */

0x08, /* 0b1000 IN4 */

0x09 /* 0b1001 IN4 + IN1 */

};

/* Initialization */

uint8_t a_28byj_48_init(TIM_HandleTypeDef *tim_handle) {

a_28byj_48_tim_handle = *tim_handle;

TIM_OC_InitTypeDef sConfig = {0};

/* Configure timer for 1 MHz frequency */

a_28byj_48_tim_handle.Init.Prescaler = (SystemCoreClock / 1000000) - 1;

a_28byj_48_tim_handle.Init.CounterMode = TIM_COUNTERMODE_UP;

a_28byj_48_tim_handle.Init.Period = 100 - 1; /* 10 kHz PWM frequency */

a_28byj_48_tim_handle.Init.ClockDivision = TIM_CLOCKDIVISION_DIV1;

a_28byj_48_tim_handle.Init.AutoReloadPreload = TIM_AUTORELOAD_PRELOAD_ENABLE;

if (HAL_TIM_PWM_Init(&a_28byj_48_tim_handle) != HAL_OK) {

return 1; /* Initialization failed */

}

sConfig.OCMode = TIM_OCMODE_PWM1;

sConfig.Pulse = 0; /* Default off */

sConfig.OCPolarity = TIM_OCPOLARITY_HIGH;

sConfig.OCFastMode = TIM_OCFAST_ENABLE;

if (HAL_TIM_PWM_ConfigChannel(&a_28byj_48_tim_handle, &sConfig, MOTOR_28BYJ_48_IN1) != HAL_OK ||

HAL_TIM_PWM_ConfigChannel(&a_28byj_48_tim_handle, &sConfig, MOTOR_28BYJ_48_IN2) != HAL_OK ||

HAL_TIM_PWM_ConfigChannel(&a_28byj_48_tim_handle, &sConfig, MOTOR_28BYJ_48_IN3) != HAL_OK ||

HAL_TIM_PWM_ConfigChannel(&a_28byj_48_tim_handle, &sConfig, MOTOR_28BYJ_48_IN4) != HAL_OK) {

return 2; /* Channel configuration failed */

}

HAL_TIM_PWM_Start(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN1);

HAL_TIM_PWM_Start(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN2);

HAL_TIM_PWM_Start(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN3);

HAL_TIM_PWM_Start(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN4);

return 0; /* Initialization success */

}

/* Update PWM signals for motor control */

void a_28byj_48_update_pwm(uint8_t step_value, uint16_t speed)

{

__HAL_TIM_SET_COMPARE(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN1, (step_value & 0x01) ? speed : 0);

__HAL_TIM_SET_COMPARE(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN2, (step_value & 0x02) ? speed : 0);

__HAL_TIM_SET_COMPARE(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN3, (step_value & 0x04) ? speed : 0);

__HAL_TIM_SET_COMPARE(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN4, (step_value & 0x08) ? speed : 0);

}

/* Stop the motor */

uint8_t a_28byj_48_stop(void)

{

/* Set all PWM outputs to 0 to stop the motor */

__HAL_TIM_SET_COMPARE(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN1, 0);

__HAL_TIM_SET_COMPARE(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN2, 0);

__HAL_TIM_SET_COMPARE(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN3, 0);

__HAL_TIM_SET_COMPARE(&a_28byj_48_tim_handle, MOTOR_28BYJ_48_IN4, 0);

return 0;

}

/* Rotate the motor */

uint8_t a_28byj_48_rotate(motor_step_mode_t step_mode, uint16_t time_delay_us, uint8_t direction)

{

const uint8_t *step_sequence = step_mode == STEP_MODE_HALF ? step_sequence_half : step_sequence_full;

uint8_t step_count = step_mode == STEP_MODE_HALF ? 8 : 4;

if (direction) {

current_step = (current_step + 1) % step_count; /* Clockwise */

} else {

current_step = (current_step - 1 + step_count) % step_count; /* Counterclockwise */

}

uint8_t step_value = step_sequence[current_step];

a_28byj_48_update_pwm(step_value, 100);

/* Clamp delay between 560 and 9000 us */

time_delay_us = (time_delay_us < 560) ? 560 : (time_delay_us > 9000 ? 9000 : time_delay_us);

delay_us(time_delay_us);

return 0;

}

/* Lock the motor at the current position */

void a_28byj_48_lock_position(void)

{

uint8_t step_value = current_step < 4 ? step_sequence_full[current_step] : step_sequence_half[current_step];

a_28byj_48_update_pwm(step_value, 100);

}

/**

* a_28byj_48_set_speed

* Set the speed of the motor by adjusting the delay between steps.

*

* @param step_mode: The step mode (STEP_MODE_FULL or STEP_MODE_HALF).

* @param speed_rpm: Desired speed in revolutions per minute (RPM).

*

* @return time_delay_us: Computed delay in microseconds for the desired speed.

*

* 通过参数 RPM 来设置目标转速(转/分钟),通过目标转速计算出不同步进模式下,每步需要的时间

*

* 每步延时的时间(每步的目标时间 ,微秒)= 每分钟的微秒数 / 每分钟的步数 = (60 * 10^6) / (RPM * 每圈步数)

*/

uint16_t a_28byj_48_set_speed(motor_step_mode_t step_mode, float speed_rpm)

{

float steps_per_revolution = step_mode == STEP_MODE_HALF ? 4096.0 : 2048.0;

uint16_t time_delay_us = (uint16_t)((60.0 * 1000000.0) / (speed_rpm * steps_per_revolution));

if (time_delay_us < 560) {

time_delay_us = 560;

} else if (time_delay_us > 9000) {

time_delay_us = 9000;

}

return time_delay_us;

}

/**

* a_28byj_48_step_angle

* Rotate the motor by a specific angle.

*

* @param step_mode: The step mode (STEP_MODE_FULL or STEP_MODE_HALF).

* @param angle: The angle to rotate in degrees.

* @param direction: Direction of rotation (1 for clockwise, 0 for counterclockwise).

*

* @return 0 if successful, 1 if an error occurs.

*

* 28BYJ-48 是4相8拍步进电机,其内部结构决定了步进电机内部转子每步旋转的角度(步进角,从一相旋转到相邻的下一相的角度)为11.25°

* 28BYJ-48 电机内部有一个减速齿轮组,该减速比为64:1 这意味着电机的内部转子需要旋转 64 圈,才能让外部输出轴旋转 1 圈

*

* 28BYJ-48 电机的步进角为 11.25°。

* 每转需要的基本步数(未经过减速)为 360° / 11.25° = 32步

* 由于 28BYJ-48 的减速比为 64:1,输出轴每转一圈需要内部转子转动 64 圈。

* 因此,经过减速后,输出轴每转一圈需要的步数为 32 步/圈 * 64 圈 = 2048 步

*

* 在整步模式下,步进电机的完整旋转步数就是 2048 步。

*

* 在半步模式下,每次步进电机的角度是整步模式的一半,即 5.625°

* 每个完整步分为两个半步,每转需要的基本步数(未经过减速)为 360° / 5.625° = 64步

* 经过 64:1 的减速比后,输出轴每转一圈需要的步数为 64 步/圈 * 64 圈 = 4096 步

*

* 在半步模式下,步进电机的完整旋转步数就是 4096 步。

*

* 减速比的存在是为了增加输出轴的精度和力矩,通过 64:1 的减速比后,输出轴可以达到 整部模式下 0.17578125° 的精度,半步模式下 0.087890625° 的精度,但是这会牺牲旋转的速度

*

*/

uint8_t a_28byj_48_step_angle(motor_step_mode_t step_mode, float angle, uint8_t direction) {

const uint8_t *step_sequence = step_mode == STEP_MODE_HALF ? step_sequence_half : step_sequence_full;

uint8_t step_count = step_mode == STEP_MODE_HALF ? 8 : 4;

float steps_per_revolution = step_mode == STEP_MODE_HALF ? 4096.0 : 2048.0;

uint16_t total_steps = (uint16_t)((angle / 360.0) * steps_per_revolution);

for (uint16_t i = 0; i < total_steps; i++) {

if (direction) {

current_step = (current_step + 1) % step_count;

} else {

current_step = (current_step - 1 + step_count) % step_count;

}

uint8_t step_value = step_sequence[current_step];

a_28byj_48_update_pwm(step_value, 100);

delay_us(1000);

}

return 0;

}

/* Continuous motor rotation */

void a_28byj_48_continuous_rotation(motor_step_mode_t step_mode, float speed_rpm, uint8_t direction)

{

uint16_t time_delay_us = a_28byj_48_set_speed(step_mode, speed_rpm);

while (1) {

a_28byj_48_rotate(step_mode, time_delay_us, direction);

}

}

/* Toggle motor direction */

void a_28byj_48_toggle_direction(uint8_t *current_direction)

{

*current_direction = (*current_direction == 1) ? 0 : 1;

}

uint8_t a_28byj_48_rotation_clockwise(motor_step_mode_t step_mode, uint16_t time_delay_us) {

return a_28byj_48_rotate(step_mode, time_delay_us, 1);

}

uint8_t a_28byj_48_rotation_counterclockwise(motor_step_mode_t step_mode, uint16_t time_delay_us) {

return a_28byj_48_rotate(step_mode, time_delay_us, 0);

}

/************************* 中级功能 *************************** */

/**

* a_28byj_48_position_control

* Move the motor to a specific position in steps.

*

* @param step_mode: The step mode (STEP_MODE_FULL or STEP_MODE_HALF).

* @param target_position: The desired position in steps.

* @param current_position: Pointer to the current position in steps.

* @param time_delay_us: Delay between steps for speed control.

*

* @return 0 if successful, 1 if an error occurs.

*/

uint8_t a_28byj_48_position_control(motor_step_mode_t step_mode, int32_t target_position, int32_t *current_position, uint16_t time_delay_us)

{

int32_t steps_to_move = target_position - *current_position; /* Calculate the difference */

uint8_t direction = (steps_to_move > 0) ? 1 : 0; /* Determine direction */

steps_to_move = abs(steps_to_move); /* Get the absolute number of steps to move */

for (int32_t i = 0; i < steps_to_move; i++) {

/* Rotate one step in the determined direction */

a_28byj_48_rotate(step_mode, time_delay_us, direction);

/* Update current position */

*current_position += (direction ? 1 : -1);

}

return 0;

}

/**

* a_28byj_48_microstep_drive

* Drive the motor in microstep mode for smoother motion.

*

* @param step_mode: The step mode (STEP_MODE_FULL or STEP_MODE_HALF).

* @param microstep_count: Number of microsteps to perform.

* @param time_delay_us: Delay between microsteps for speed control.

* @param direction: Direction of rotation (1 for clockwise, 0 for counterclockwise).

*

* @return 0 if successful, 1 if an error occurs.

*/

uint8_t a_28byj_48_microstep_drive(motor_step_mode_t step_mode, uint16_t microstep_count, uint16_t time_delay_us, uint8_t direction)

{

/* Example: Divide each step into 16 microsteps */

uint16_t microsteps_per_step = 16;

uint16_t total_steps = microstep_count / microsteps_per_step;

for (uint16_t step = 0; step < total_steps; step++) {

for (uint16_t microstep = 0; microstep < microsteps_per_step; microstep++) {

/* Perform a fraction of the step */

a_28byj_48_rotate(step_mode, time_delay_us / microsteps_per_step, direction);

}

}

return 0;

}

/**

* a_28byj_48_accel_decel_drive

* Drive the motor with acceleration and deceleration.

*

* @param step_mode: The step mode (STEP_MODE_FULL or STEP_MODE_HALF).

* @param total_steps: Total number of steps to move.

* @param max_speed_rpm: Maximum speed in RPM.

* @param acceleration: Steps to accelerate to max speed.

* @param deceleration: Steps to decelerate from max speed.

* @param direction: Direction of rotation (1 for clockwise, 0 for counterclockwise).

*

* @return 0 if successful, 1 if an error occurs.

*/

uint8_t a_28byj_48_accel_decel_drive(motor_step_mode_t step_mode, uint16_t total_steps, float max_speed_rpm, uint16_t acceleration, uint16_t deceleration, uint8_t direction)

{

uint16_t time_delay_us;

uint16_t current_speed_step = 0;

/* Accelerate */

for (uint16_t step = 0; step < acceleration && step < total_steps; step++) {

current_speed_step++;

time_delay_us = a_28byj_48_set_speed(step_mode, (max_speed_rpm * current_speed_step) / acceleration);

a_28byj_48_rotate(step_mode, time_delay_us, direction);

}

/* Constant speed */

for (uint16_t step = acceleration; step < total_steps - deceleration; step++) {

a_28byj_48_rotate(step_mode, time_delay_us, direction);

}

/* Decelerate */

for (uint16_t step = 0; step < deceleration && step < total_steps; step++) {

current_speed_step--;

time_delay_us = a_28byj_48_set_speed(step_mode, (max_speed_rpm * current_speed_step) / deceleration);

a_28byj_48_rotate(step_mode, time_delay_us, direction);

}

return 0;

}

总结

-

首先需要熟悉步进电机28BYJ-48的机构,工作原理。驱动拍的工作特点。驱动的步进角公式会计算。

-

驱动库编写需要针对不同驱动电路的设计,驱动电路的使用工作原理。ULN2003驱动电路特点,输入和输出是反相,输入高电平,驱动输出端拉低,驱动绕组励磁工作。

-

能力有限,有错误地方欢迎指正。